Description

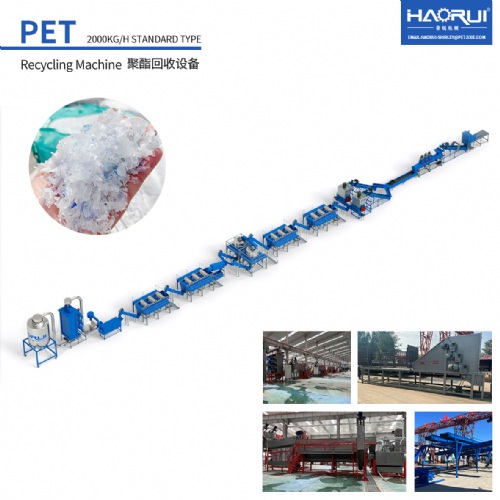

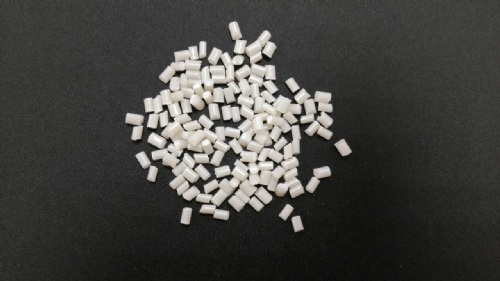

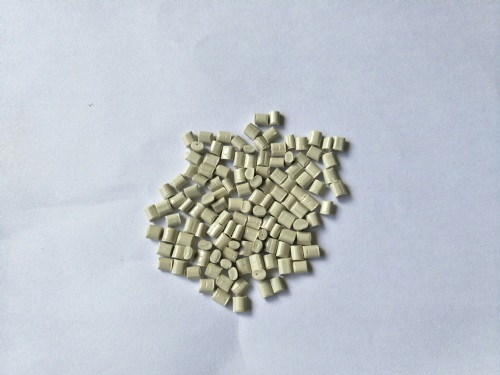

The production line has a capacity of 4,000 to 5,000 kg/h. It is suitable for companies with 3 to 5 years of experience in this industry and strong capabilities. Generally, the production line mainly includes: a bale opener, a trommel screen, a bottle pre-washing system, a label remover, a bottle sorting machine, a manual sorting platform, a belt conveyor, a crusher, a screw loader, a floating washing tank, a hot washing tank, a high-speed friction washer, a dewatering machine, a zig-zag label separator, a color sorter, a polymer sorter, and silo storage. This line adopts automatic bottle sorting and flakes sorting, with high resolution, and finally produces high-quality, pure, single-color and translucent PET flakes, meeting the 3A food grade standard. We can provide customization according to customers' requirements.

Related Products

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry