Exhibitor Profile

TOYO KOHAN SHANGHAI CO., LTD.

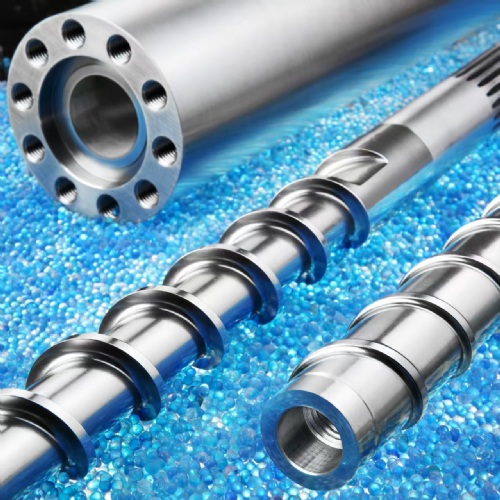

KH Screw construction and special characteristics KH is attached to the metal core (SCM440) using the reactive sintering method. Thanks to this processing method KH is not only covering the surface of the screw- screw flights are actually 100% made out of it.As a result- the screw can last extraordinarily long even against resin materials like plastic magnet (high abrasion) or halogen-free resins(extremely corrosive). KH Cylinder construction and special characteristics 4 mm thick KH inner tube is attached to SCM440 metal outer tube by shrinking process.4mm thick layer of hardened material is much more than in case of products from other manufacturers. Due to this characteristics - KH products shows extraordinary durability against abrasion and therefore is very recommended to use with resin materials containing high percentage of Glass Fiber or other highly-aggressive types of resins.Moreover - thanks to using the shrinking process- inner tub is being pressurized from outside. It makes it very strong against any pressure pushing from the inside and conse-quently makes KH cylinder very recommended for clients working with very high injection pressure in their process

• Area:

Plastic Industry Fair

• Booth No:

112

• Website:

https://www.tkworks.jp/

• Brands:

TOYO KOHAN

You may also like

Highest Rated Exhibitors

SHANGHAI CMIC MACHINERY AND ELECTRICAL PRODUCTS CO., LTD.

CONG TY TNHH HUANYU AUTOMATION VINA

CONG TY THMM MAY EP NHUA HONZEN UNION VIET NAM

FU CHUN SHIN (VIETNAM) COMPANY LIMITED

CHAO WEI PLASTIC MACHINERY CO., LTD.

JWELL MACHINERY (CHANGZHOU) CO., LTD

CONG TY TNHH SHOUXI

ZHEJIANG NANYI PLASTIC MACHINERY CO., LTD

HIEP HOI NHUA VIET NAM (VPA)

INEM CO., LTD.

MULTITECH MACHINERY LIMITED

SIL-MORE INDUSTRIAL LTD.

KAIZER PVC ADDITIVES SDN BHD

RR PLAST EXTRUSIONS PVT LTD

TAN HUNG CO MANUFACTURING AND TRADING COMPANY LIMITED

CONG TY TNHH DAU TU PHAT TRIEN THUONG MAI HONG THAI

CONG TY CO PHAN AN PHU BIOPLASTIC

ZHOUSHAN PHAETON INTERNATIONAL TRADE CO., LTD.

ZHEJIANG JINTENG MACHINERY MANUFACTURE CO.,LTD

JON WAI MACHINERY WORKS CO., LTD.

DAISAKU CO., LTD.

TOYO KOHAN SHANGHAI CO., LTD.

HONCERE TECHNOLOGY COMPANY LIMITED

CONG TY TNHH KY THUAT HOANG THIEN LONG (HTL TECH CO., LTD.)

DATACOLOR ASIA PACIFIC (HK) LIMITED

SHINI PLASTICS TECHNOLOGIES, INC.

CONG TY TNHH HOA CHAT MINH LONG

CONG TY TNHH GIA CONG VA XUAT NHAP KHAU HOA VIET

CONG TY TNHH CONG NGHE PROCHEM (HA NOI)

KINH DOANH NHUA TAI CHE_TIEUS ENT. LTD.

Back

Exhibitor Inquiry

Exhibitor Inquiry